BMW Group Plant Leipzig to start battery module production in 2021

The BMW Group is further expanding its Germany- based production capacities for electric drives. From 2021, the Leipzig plant will also produce battery modules for the high-voltage batteries of the BMW Group’s electrified vehicles.

By 2022, the company is investing more than €100 million ($117 million) in the site to prepare for the steadily increasing sales of electrified vehicles, strengthening its role as a pioneer in e-mobility.

The new production location was announced in Leipzig by Michael Nikolaides, Head of Planning and Production Engines and E-Drives, and Hans-Peter Kemser, Director of BMW Group Plant Leipzig, at an event with the Governor of Saxony, Michael Kretschmer, and the Lord Mayor of Leipzig, Burkhard Jung.

“We are consistently ramping up the production of e-drives to meet our ambitious electric mobility targets,” explained Nikolaides. “Just recently, we opened our Competence Center for E-drive Production in Dingolfing and doubled the production capacity for high-voltage batteries at BMW Brilliance Automotive in China by opening another battery center. Now we are also stepping up our battery production output in Germany,” he added.

“We are delighted to once again bring e-mobility to Leipzig,” said Hans-Peter Kemser. “We are investing more than 100 million euros in setting up the battery module production on premises comprising a total of 10,000 square meters.”

The large-series production of battery modules at the Leipzig site is scheduled to start as early as in mid-2021. The Leipzig site is the e-mobility pioneer among the BMW Group’s plants. As the production site of the BMW i3, the BMW Group’s first all-electric vehicle, it has been involved in electric mobility since 2013.

“We have many people on our team here in Leipzig with great e-mobility expertise. We are now contributing this expertise to the production of high-voltage batteries. By 2022, more than 150 people will be working in battery module production at the site,” explained Kemser.

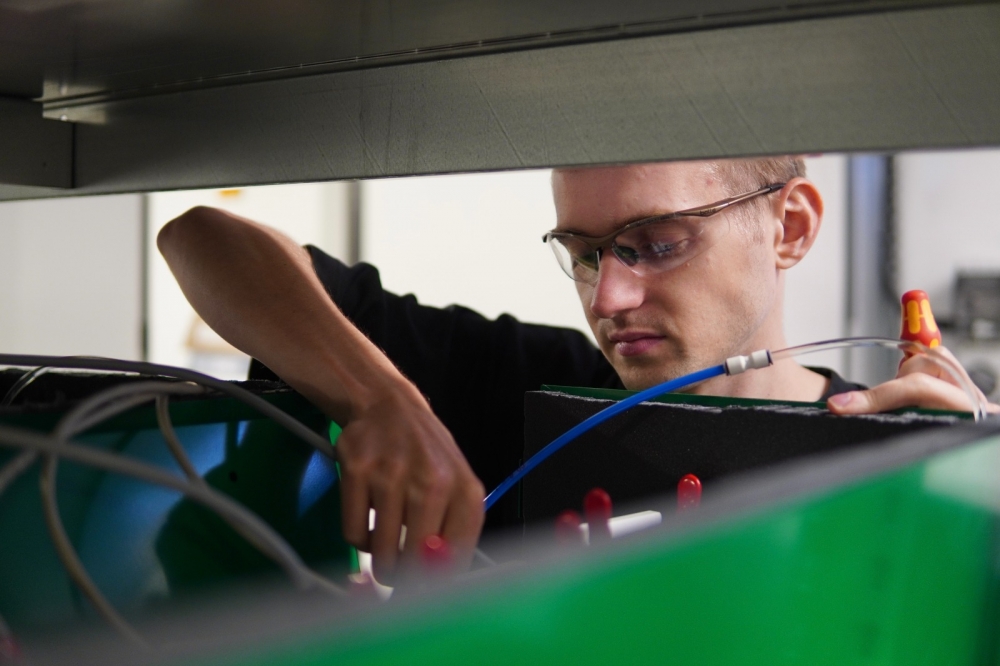

The production process for high-voltage batteries consists of two main steps: First, the battery cells are tested and then assembled into larger units, the battery modules, in a highly automated process. The BMW Group procures the battery cells from partners who produce them according to the BMW Group’s precise specifications. The BMW Group uses different battery cells, depending on which one provides the best characteristics for the relevant vehicle concept.

The battery modules are then mounted into an aluminum casing along with the vehicle connectors, control units and cooling units. The size and shape of the aluminum casing as well as the number of battery modules used vary depending on the vehicle variant. The result is a high-voltage battery ideally adapted to the vehicle.

This combination of standardised battery modules and casings flexibly adapted to the vehicle has several advantages: Firstly, it ensures uniform properties and quality standards in the production of the high-voltage batteries. Secondly, the modular design of the high-voltage battery serves as the basis for a wide range of e-drive variants. Last but not least, this modular approach is a crucial prerequisite for being able to respond quickly to customer demand and take advantage of cost savings.

To date, the high-voltage batteries for all electrified vehicles of the BMW and MINI brands have been produced at the three in-house battery production facilities in Dingolfing/Germany, Spartanburg/USA and Shenyang/China. The new battery module production at BMW Group Plant Leipzig will join this network from 2021 onward.

As early as 2021, one in four BMW Group vehicles sold in Europe is expected to be fitted with an electric drive. By 2025, it’ll be one in three, and one in two by 2030. In 2023, the BMW Group will have 25 electrified models on the road, half of which will be fitted with an all-electric drive.

BMW Group Plant Leipzig to start battery module production in 2021

Modified on Wednesday 23rd September 2020

Find all articles related to:

BMW Group Plant Leipzig to start battery module production in 2021

Add to my Reading List

Add to my Reading List Remove from my Reading List

Remove from my Reading List