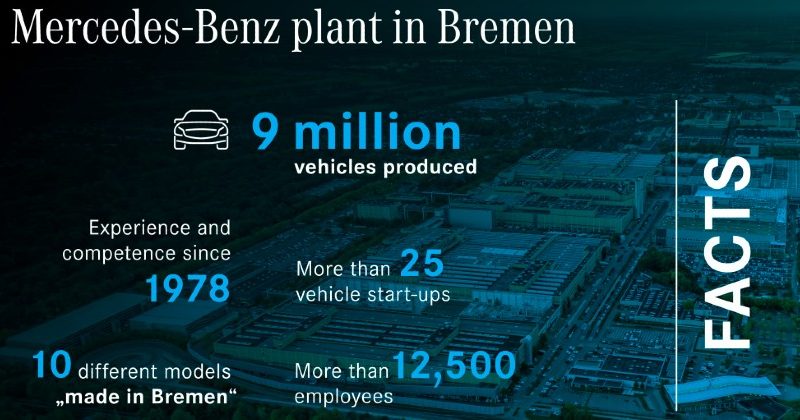

Mercedes-Benz Bremen Plant produces the nine millionth three-pointed star

The Mercedes-Benz Bremen Plant is celebrating a special anniversary: An EQC (combined power consumption: 21.3-20.2 kWh/100 km; combined CO2 emissions: 0 g/km), the Mercedes-Benz among electric vehicles, is the nine millionth vehicle “made in Bremen” to roll off the assembly line.

The EQC is one of ten models that are successfully produced at the site. Within the global production network of Mercedes-Benz Cars, Bremen is the centre of competence for the worldwide production of the C-Class, which has been Mercedes-Benz’s highest-volume model for more than ten years. Bremen is also responsible for the global production of the GLC as well as of the all-electric EQC. With a flexible production of vehicles with different powertrain variants, the Bremen site contributes to the efficiency and productivity of the entire production network.

The Mercedes-Benz Bremen Plant looks back on a history of over 40 years. The production of Mercedes-Benz passenger cars in Bremen started in February 1978 with the Estate model of the 123 model series. Since then, the plant has already successfully mastered more than 25 vehicle start-ups and pursues the long tradition of automotive construction in the Hanseatic City. To this day, the Bremen team is distinguished by its great experience with start-ups and the flexible integration of new models.

“The Mercedes-Benz Bremen Plant is an excellent example for the diversity and flexibility of our Mercedes-Benz Cars global production network. With a Mercedes-Benz EQC we have now reached the nine-million mark. We are very proud of this new production anniversary in our global network. With state-of-the-art technologies at the site we produce vehicles with different body styles and powertrains – from conventional to all-electric powertrains. We flexibly integrate new future technologies into ongoing production and are able to produce different models on one line,” says Jörg Burzer, Member of the Board of Management of Mercedes-Benz AG, Production and Supply Chain Management.

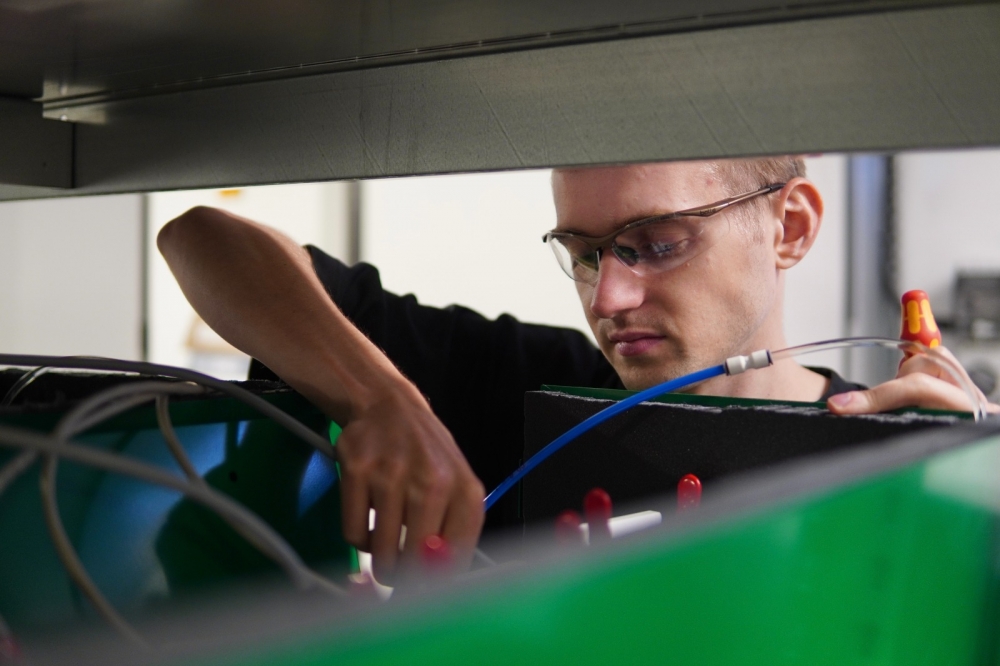

The EQC was the first all-electric vehicle to be integrated into ongoing production in 2019. It is produced there on the same line as the C-Class Saloon and Estate as well as the GLC and GLC Coupé. This is possible because Mercedes-Benz Cars invested in high-tech equipment with pioneering Industry 4.0 solutions in the entire production network at an early stage.

“Since I took over the role of location manager of the Mercedes-Benz Bremen Plant in April 2020, I have been inspired by the great commitment of our team and by how they put their hearts and souls into mastering every task. This fantastic anniversary is the result of a strong team performance and once more proves the great expertise of the employees of our location,” says Michael Frieß, Location Manager and Head of Production of the Mercedes-Benz Bremen Plant.

With a workforce of more than 12,500, the Mercedes-Benz Bremen Plant is the largest private-sector employer in the region.

“The 9 millionth vehicle from our Bremen plant shows the successful and great work that our colleagues have done over decades and which is appreciated by our customers. At this point, I would like to thank everyone who was involved in this,” says Michael Peters, Chairman of the Works Council at the Bremen site.

Successful production conversion of the E-Class

The Bremen plant also demonstrated complete flexibility during the latest production start-up. Not least due to the wide model diversity the Bremen team has great experience in start-ups. The production conversion of the comprehensively updated model series of the new E-Class took place in July 2020. In Bremen the Mercedes-Benz E-Class Coupé and Cabriolet are produced. Flexibility is a crucial factor of success here as well: The E-Class is produced on one line with the C-Class Coupé and the C-Class Cabriolet, a process that uses innovative, sophisticated technologies: One example is the digital shopfloor management, which allows monitoring current production data in real time. The QUALITY LIVE system enables the employees to check the quality of every vehicle in real time on a clearly arranged user interface. QUALITY LIVE and the digital shopfloor management are components of the MO360 digital production ecosystem of Mercedes-Benz Cars. The advantage is that MO360 makes it possible to increase the efficiency significantly.

About the Mercedes-Benz Bremen Plant

Ten models are currently produced at the location: C-Class Saloon, Estate, Coupé and Cabriolet; E-Class Coupé and Cabriolet; the SUV GLC, GLC Coupé as well as the SL Roadster and the EQC. More than 360,000 vehicles were produced in Bremen in 2019. As the centre of competence for the C-Class, the Mercedes-Benz Bremen Plant oversees the worldwide production of Mercedes-Benz’s highest-volume model series at the company’s overseas plants. Also the production of the GLC is controlled from Bremen as the main production location. Vehicles “Made in Bremen” cover the whole range of intelligent powertrains – from traditional combustion engines and plug-in hybrids to electric vehicles.

Mercedes-Benz Bremen Plant produces the nine millionth three-pointed star

Modified on Wednesday 16th September 2020

Find all articles related to:

Mercedes-Benz Bremen Plant produces the nine millionth three-pointed star

Add to my Reading List

Add to my Reading List Remove from my Reading List

Remove from my Reading List