Equipmake collaborates with HiETA to create a power dense electric motor

One of the world’s most power dense permanent magnet electric motor is under development in the UK.

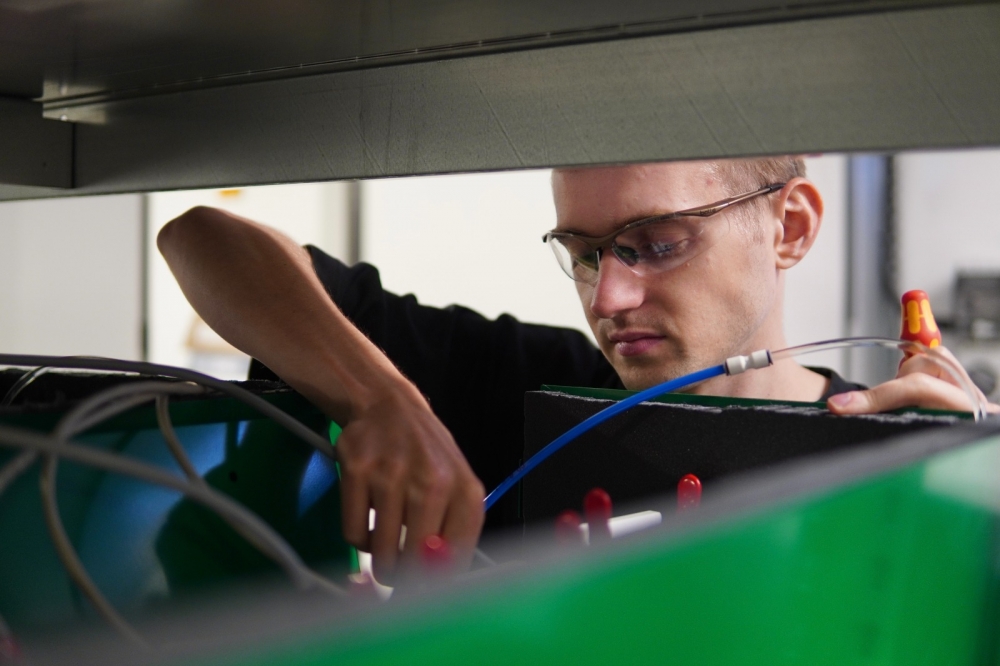

Expert electrification company, Equipmake, has teamed up with leading additive manufacturing organisation HiETA to develop the next-generation motor as part of a revolutionary project, grant-funded by Innovate UK.

Codenamed AMPERE, the new motor will draw on Equipmake’s expertise in electric motor design and HiETA’s pioneering knowledge in thermal engineering and additive manufacturing with the target of producing an extremely lightweight, efficient but low-cost electric motor with peak power density of more than 20kW per kg – more than four times as power dense as a conventional electric motor.

The key to AMPERE’s performance is its combination of an advanced motor design with additive manufacturing, allowing its metal structure to be 3D printed, rather than milled from a solid billet. This brings many advantages. Firstly, metal is only put where it is needed. Secondly, thermally efficient thin walls and optimised fine surface details can be combined directly with the motor’s structure, replacing multi-part assemblies with a single, complex architecture that has exceptional cooling ability, is lightweight, has low inertia and allows for greatly increased rotational speed.

This approach not only means that AMPERE will use the least amount of high strength alloys in its construction, but also the least amount of expensive active materials – the magnets – too, keeping cost as low as possible.

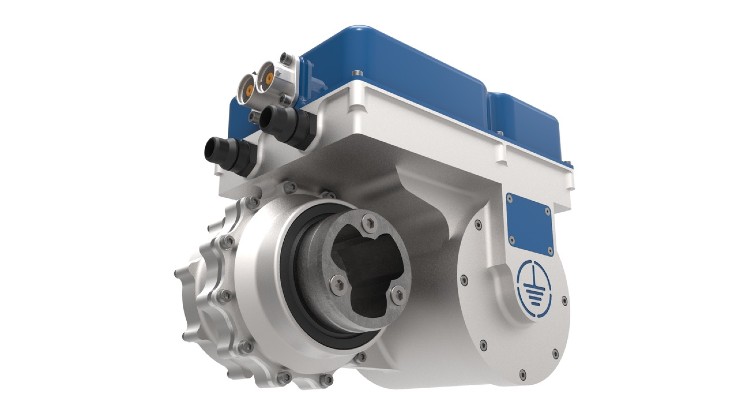

Equipmake and HiETA are targeting peak power of 220kW at 30,000rpm and a weight of less than 10kg for AMPERE. By comparison, even the best standard permanent magnet motors in use today would struggle to muster 5kW per kg. Equipmake’s innovative APM 125, one of the world’s most power dense automotive electric motors, which uses the company’s spoke architecture to maximise cooling capability, offers peak power of 125kW at 12,000rpm and a weight of just 14kg, giving it power density of just under 9kW per kg. The first AMPERE prototypes are set to be up and running in 12 months’ time.

At the end of last year, Equipmake opened its all-new factory in Snetterton, Norfolk, where the company provides the complete electric vehicle solution, offering the capability to design, test and manufacture everything from motors to fully electrified platforms, supporting the automotive and aerospace sectors. On site, it designs and manufactures its fully-integrated electric bus chassis for an increasingly international customer base. Its innovative APM range of motors are used by its EBus chassis and will also power the upcoming Ariel HIPERCAR.

Ian Foley, Managing Director of Equipmake, said: “Equipmake has made major leaps in electric motor performance in recent years, with our APM range of advanced motors offering class-leading power densities thanks to their compact, lightweight designs. Additive manufacturing is the key to unlocking the next step change and we are delighted to be partnering with HiETA on AMPERE. This exciting project has the potential to totally change our concept of what an electric motor can offer – and with such a huge amount of performance in a such a small package at as low a cost as possible, this motor is set to further revolutionise e-mobility, whether that’s in automotive or aerospace.”

Andy Jones, Innovation Programme Manager at HiETA, said: “AMPERE provides the opportunity to apply both HiETA’s thermal management expertise and complex, thin walled structure manufacture enabled by additive manufacture to electric motor design to realise ambitious power densities. We typically reduce the size of thermal management components by five times compared with conventional techniques which will allow next generation heat transfer features to be integrated into the rotor, stator and electronics cooling. In addition, the freedoms of additive manufacture will be used to optimise structural performance. We are integrating these benefits with Equipmake’s advanced electric motor design from the ground up and are looking forward to manufacture and test in the near future.”

Equipmake collaborates with HiETA to create a power dense electric motor

Modified on Wednesday 4th March 2020

Find all articles related to:

Equipmake collaborates with HiETA to create a power dense electric motor

Add to my Reading List

Add to my Reading List Remove from my Reading List

Remove from my Reading List